Common Steel Standard

| Steel Type | Metal Code | Standard | |

| Austenitic Steel | USA | CF8 | ASTM A 351/A351M |

| CF8M | ASTM A 351/A351M | ||

| CF3M | ASTM A 351/A351M | ||

| CN7M | ASTM A 351/A351M | ||

| Germany | 1.4308/GX5CINi9-10 | DIN EN 10213-4 | |

| 1.4408/GX6CINiMo19-11-2 | DIN EN 102134 | ||

| 1.4409/GX2CINiM019-11-2 | DIN EN 102134 | ||

| 1.4581/GX5CINMoNb19-11-2 | DIN EN 10213-4 | ||

| Japan | SCS 13 | JIS G 5121 | |

| SCS14 | JIS G 5121 | ||

| SCS16 | JIS G 5121 | ||

| British | 304C15 | BS 3100 | |

| 316 C16 | BS 3100 | ||

| 316 C12 | BS 3100 | ||

| 347C17 | BS 3100 | ||

| ANC 4 Grade A | BS 3146:Part 2 | ||

| ANC 4 Grade B | BS 3146:Part 2 | ||

| ANC 4 Grade C | BS 3146:Part 2 | ||

| Duplex Steel | USA | CD4Mcu/Grade 1A | ASTM A 890/A890M |

| CD3MN/Grade 4A | ASTM A 890/A890M | ||

| 5A(CE3MN) | ASTM A 890/A890M | ||

| Germany | 1.4517/GX2CNiMoCuN25-6-33 | DIN EN 102134 | |

| Japan | SCS10 | JISG 5121 | |

| British | ANC 6/Grade A | BS 3146:Part 2 | |

| ANC 21 | BS 3146:Part 2 | ||

| Carbon Steel | USA | WCA | ASTM A 216/A216M |

| WCB | ASTM A 216/A216M | ||

| WCC | ASTM A 216/A216M | ||

| WC6 | ASTM A 217/A217M | ||

| WC9 | ASTM A 217/A 217M | ||

| Germany | 1.0619/GP240GH/GS-C25 | DIN EN 10213-2 | |

| 1.7357/G17CrM05-5 | DIN EN 10213-2 | ||

| British | A4 | BS 3100 | |

| Ni-based Alloy | USA | CW2M/Hastelloy C | ASTM A 494/A494M |

| N7M/Hastelloy B | ASTM A 494/A494M | ||

| M-35-1/Monel | ASTM A 494/A494M | ||

| M-35-2/Monel | ASTM A 494/A494M | ||

| Martensitic Steel | USA | CA15 | ASTM A 217/A217M |

| CA-40 | ASTM A 743/A743M | ||

| CA6NM/Grade A | ASTM A 487/A487M | ||

| Germany | 1.4317/GX4CrNi134 | DIN EN 10213-2 | |

| 1.4405/GX4CNo16-5-1 | DIN EN 10213-2 | ||

| 1.4059/GX22CNi17 | DIN 17445 | ||

| 1.4313/GX5CIN134 | DIN 17445 | ||

| British | ANC 2 | BS 3146:Part 2 | |

Comparison of Mechanical Properties For Different Alloys

Steel alloy type | DIN Material code | Density | Tensile Strength | Yield Strength | Elongation | Hardness |

Austenitic stainless steel | 1.4308 | 7.8 | 440-640 | ≥ 200 | ≥ 30 | - |

Austenitic stainless steel | 1.4408 | 7.8 | 440-640 | ≥ 210 | ≥ 30 | - |

Martensitic stainless steel | 1.4021 | 7.8 | 650-850 | ≥ 500 | ≥ 10 | - |

Martensitic stainless steel | 1.4057 | 7.8 | 780 | 590 | 25 | 229 |

Duplex stainless steel | 1.4517 | 7.8 | 650-850 | 480 | 22 | - |

Carbon steel | 1.0619 | 7.8 | 420-600 | ≥ 240 | ≥ 22 | - |

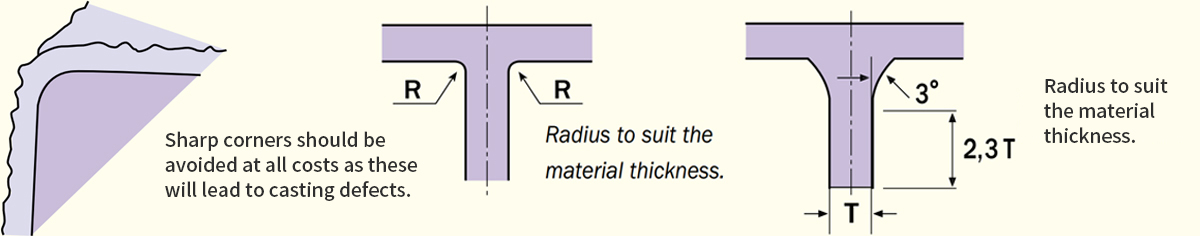

General Rules

1. Use rounded corners and fillets for improved casting quality and reduced rejection. lind holes and unnecessary strict tolerances should be avoided.

2. Generous internal and external radius, as well as uniform sections ensure improved castability

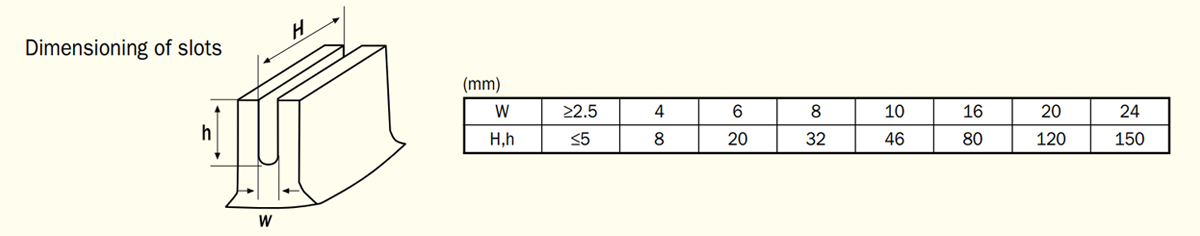

3. Dimensioning of slots

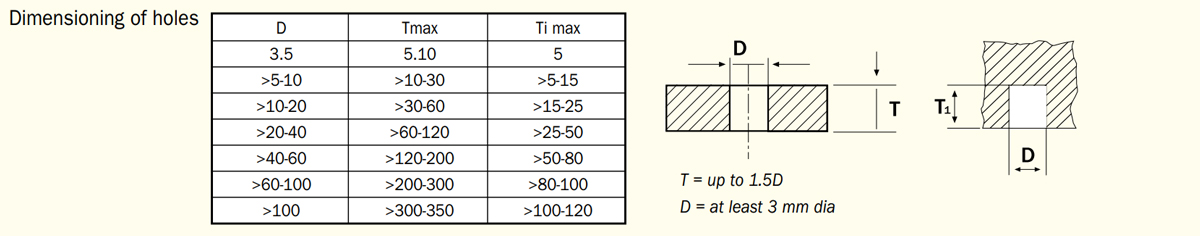

4. Dimensioning of holes

Geometrical Tolerances

It is inevitable that certain distortion are inherant in casting. To meet dimensional requirements the castings can be straightened or sized to the following general tolerance:

Angle Tolerance Normally this should be ± 1 degree and should not be closer than 1/2 degree.

Machining Allowances Allow 0.80-2.0 mm for machining. For larger workpiece add 3-4 mm.

Flatness and Straightness

Dimension (mm) | Tolerance | Dimension (in) | Dimension |

<50 | ±0.25 | <200 | ±0.010 |

50-100 | ±0.38 | 2.00-4.00 | ±0.015 |

100-105 | ±0.50 | 4.00-6.00 | ±0.020 |

150-200 | ±0.75 | 6.00-8.00 | ±0.030 |

Circularity

Dimension (mm) | Tolerance | Dimension (in) | Tolerance |

<50 | ±0.25 | <200 | ±0.010 |

50-100 | ±0.38 | 2.00-4.00 | ±0.015 |

100-105 | ±0.50 | 4.00-6.00 | ±0.020 |

150-200 | ±0.75 | 6.00-8.00 | ±0.030 |

Recommended Linear Tolerances

Dimension Range(mm) | Dimension Tolerance | ||||||

Tolerance Grade (mm) | |||||||

D1 | D2 | D3 | |||||

From | To | Both Ways | Single side | Both Ways | Single side | Both Ways | Single side |

6 | ±0.1 | 0.20 | ±0.08 | 0.16 | ±0.06 | 0.12 | |

6 | 10 | ±0.12 | 0.24 | ±0.10 | 0.20 | ±0.06 | 0.12 |

10 | 14 | ±0.15 | 0.30 | ±0.12 | 0.24 | ±0.09 | 0.18 |

14 | 18 | ±0.20 | 0.40 | ±0.14 | 0.28 | ±0.09 | 0.18 |

18 | 24 | ±0.25 | 0.50 | ±0.17 | 0.34 | ±0.12 | 0.24 |

24 | 30 | ±.030 | 0.60 | ±0.20 | 0.40 | ±0.14 | 0.28 |

30 | 40 | ±0.37 | 0.74 | ±0.25 | 0.50 | ±0.17 | 0.34 |

40 | 50 | ±0.44 | 0.88 | ±0.30 | 0.60 | ±0.2 | 0.40 |

50 | 65 | ±0.52 | 1.04 | ±0.38 | 0.76 | ±0.23 | 0.46 |

65 | 80 | ±0.60 | 1.20 | ±0.46 | 0.92 | ±0.27 | 0.54 |

80 | 100 | ±0.68 | 1.36 | ±0.53 | 1.06 | ±0.3 | 0.60 |

100 | 120 | ±0.76 | 1.52 | ±0.60 | 1.20 | ±0.33 | 0.66 |

120 | 140 | ±0.84 | 1.68 | ±0.65 | 1.30 | ±0.36 | 0.72 |

140 | 160 | ±0.92 | 1.84 | ±0.72 | 1.44 | ±0.38 | 0.76 |

160 | 180 | ±1.02 | 2.04 | ±0.80 | 1.60 | ±0.42 | 0.84 |

180 | 200 | ±1.12 | 2.24 | ±0.88 | 1.76 | ±0.43 | 0.86 |

200 | 225 | ±1.28 | 2.56 | ±0.95 | 1.90 | ±0.47 | 0.94 |

225 | 250 | ±1.44 | 2.88 | ±1.05 | 2.10 | ±0.51 | 1.02 |

250 | 280 | ±1.64 | 3.28 | ±1.15 | 2.30 | ±0.56 | 1.12 |

280 | 315 | ±1.84 | 3.68 | ±1.25 | 2.50 | ±0.63 | 1.26 |

315 | 355 | ±2.10 | 4.20 | ±1.40 | 2.80 | ±0.71 | 1.42 |

355 | 400 | ±2.40 | 4.80 | ±1.55 | 3.10 | ±0.8 | 1.60 |

400 | 450 | ±2.70 | 5.40 | ±1.70 | 3.40 | ±0.9 | 1.80 |

450 | 500 | ±3.00 | 6.00 | ±1.85 | 3.70 | ±1.00 | 2.00 |

1. Tolerance standard for investment casting is in accordance with VDG-merkblatt P-690 D2.

2.The tolerances above are the recommended minimum for functional details. For non-functional dimension, wider tolerances should be considered which will result in more economic designs.

3.Experience indicates that wider tolerances must be allowed for distances between centres of pins and holes.

4. For dimension in excess of stated range or for special tolerance requirements please contact foundry.

5. D2 is Tycon’s general accepted Dimension Tolerance.

簡体中文

簡体中文 English

English 日本語

日本語 繁体中文

繁体中文 西班牙语

西班牙语 DE

DE