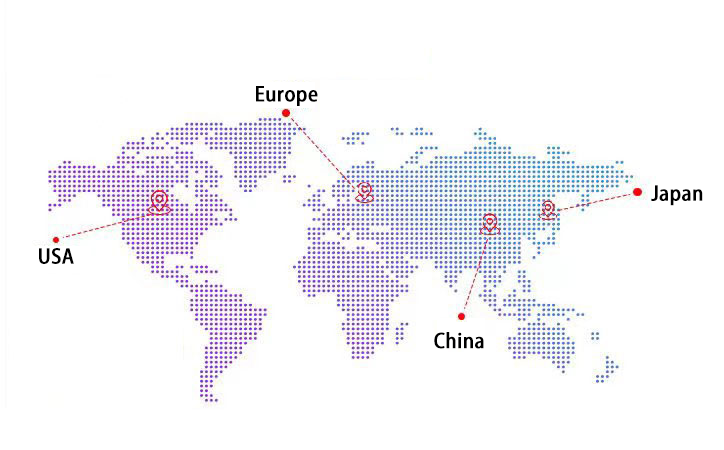

Established in 1995, Tycon has been expanding step by step with global customers’ confidence as not only a professional casting foundry to produce highly precise and complex casting components, but also a company to provide high-valued added machining and surface treatments on our produced castings. We are dedicated to be your trustworthy strategic partner to accompany along with your business.

Tycon is proud of our sustainable competence and track proficiency to customize top quality casting solutions to our customers who are themselves market leaders in their own field around the world.

簡体中文

簡体中文 English

English 日本語

日本語 繁体中文

繁体中文 西班牙语

西班牙语 DE

DE