Process Introduction

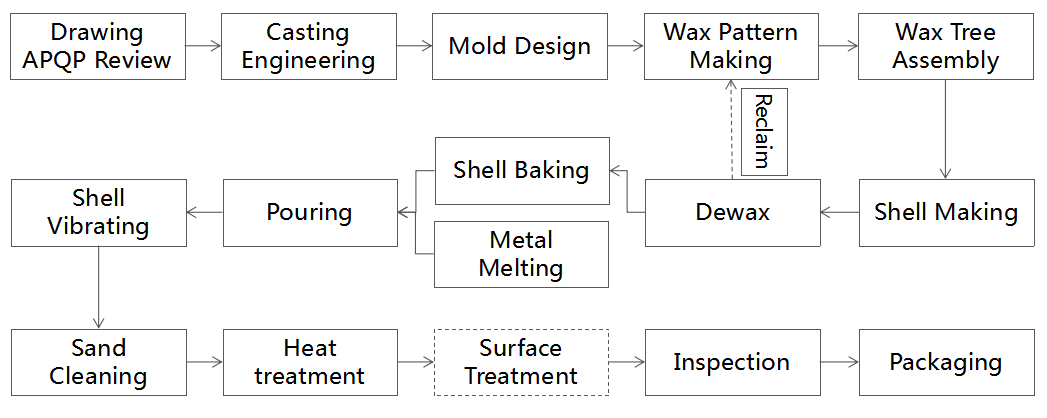

At our foundry we offer investment casting, also known as lost-wax casting. This technique allows us to produce complex shapes with excellent surface quality. From starting with a simple wax pattern, we can produce high quality parts with high dimensional accuracy for a wide range of industries.

Investment Casting Process

Capability

● Main Materials

Stainless steel, carbon steel, low alloy steel, medium alloy steel, high-manganese steel, nickel-based alloy, etc.

● Range of Weight

Unit weight range: 0.1 kg-100 kg;

● Dimensional Accuracy

VDG-MerkblattP-690-D2、DIN1680、JISB0403、ISO8062, For details please check in the quality assurance page.

● Fine Surface

≤Ra6.3,≤Ra3.2 after special process.

● Rapid Prototype

The application of 3D printing technology can meet your needs in R&D, parts maintenance, low quantity production, structural verification and fast delivery.

● Complex Structures

Our experienced engineer applied Magma casting simulation software together with the special process like ceramic core to provide engineering solutions for casting defects of complex structures, improve output and reduce scrap rate.

● Facilities

Automatic Wax Injection VA Teach Automation Shell Line Constant Temperature Drying Workshop Dewax and Wax Reclamation System Natural Gas Heat Treatment Furnace Continuous Shot Blasting

Main Investment Casting Facilities

簡体中文

簡体中文 English

English 日本語

日本語 繁体中文

繁体中文 西班牙语

西班牙语 DE

DE